The Multi-Management Furnace with Double Chamber

The two-chamber burnout furnace with an innovative system that allows the burnout of different types of material at the same time, thanks to the ability to set different temperatures for the two chambers or to turn on only one chamber at a time.

The Multi-Management Furnace with Double Chamber

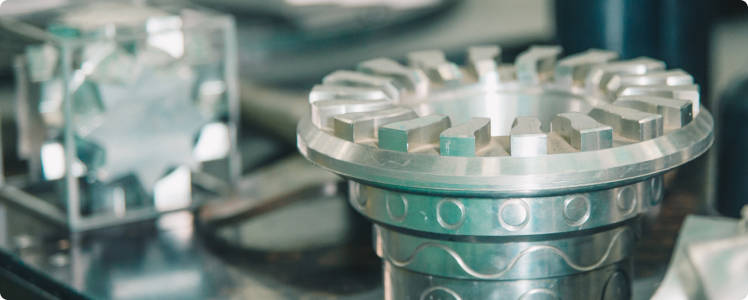

The dual-chamber rotary furnace is designed for the simultaneous bornout of various materials. The independent temperature control for each chamber optimizes energy consumption, while the innovative rotation system ensures uniform heating on all sides.

Innovative technology

Thanks to the innovative technology that involves a double movement of both the main plate and the flanges that hold the flasks, the heat is evenly distributed allowing to achieve better results.

High flask capacity

EcoTech can accommodate up to 24 rotating flanges (12 per chamber) and up to 38 flasks with Ø 100 mm if flanges are not used. Different sized flasks can be used depending on the metal.

Energy savings

The two-chamber structure allows for less heat loss while opening, as well as giving the option of operating only one chamber at a time or setting different temperatures for the two chambers.

Intuitive proprietary software for the burnout of different types of material

An intuitive 10-inch screen interface provides a seamless experience, allowing users to monitor the burnout process, current temperature, alarms, and other crucial parameters effortlessly.

Burnout parameters

Through the use of work programs, operators can set the different burnout phases and times based on the selected material, and also program a burnout sequence in advance.

Easy flask loading and unloading

After associating the reference number marked on the plaster to each cylinder on the screen, the operator can select the desired cylinder using the interface, making the plate rotate and bringing the selected cylinder to the front, ready to be collected.

Stored programs

Operators can access a list of predefined programs or set personalized programs to ensure perfect results on all materials.

Intuitive proprietary software for the burnout of different types of material

An intuitive 10-inch screen interface provides a seamless experience, allowing users to monitor the burnout process, current temperature, alarms, and other crucial parameters effortlessly.

Burnout parameters

Through the use of work programs, operators can set the different burnout phases and times based on the selected material, and also program a burnout sequence in advance.

Easy flask loading and unloading

After associating the reference number marked on the plaster to each cylinder on the screen, the operator can select the desired cylinder using the interface, making the plate rotate and bringing the selected cylinder to the front, ready to be collected.

Stored programs

Operators can access a list of predefined programs or set personalized programs to ensure perfect results on all materials.

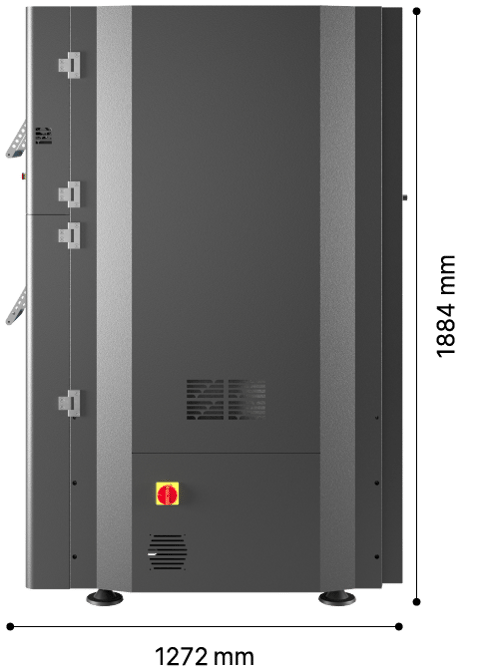

Size e dimensions

The EcoTech casting holding furnace features two independently controlled burnout chambers, accommodating up to 24 rotating flanges (12 per chamber) or 38 flasks of various sizes. This configuration optimizes energy consumption and allows for the simultaneous processing of different materials.

- Features

- Technical Data

- Accessories

- Downloads

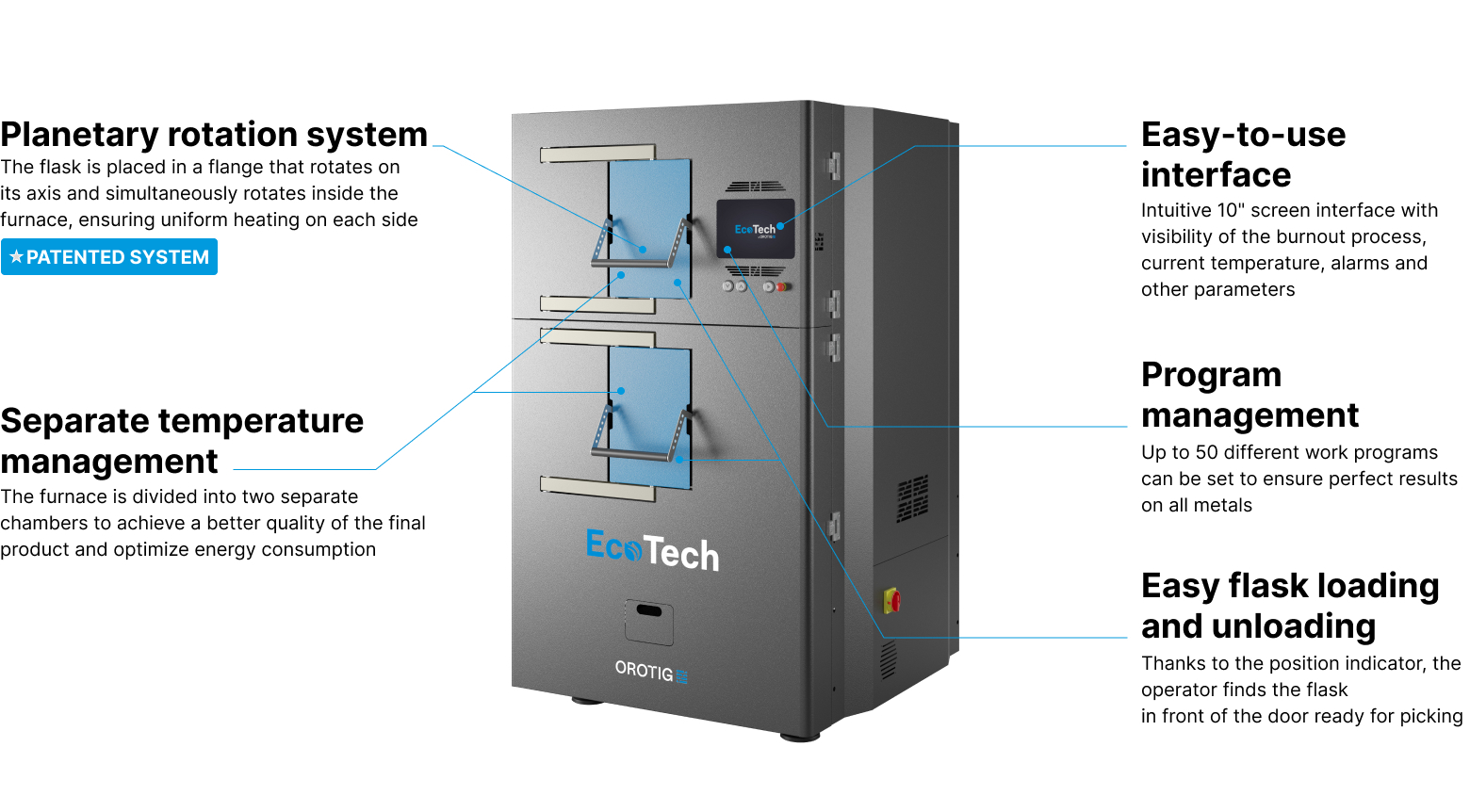

Planetary rotation system

The flask is placed in a flange that rotates on its axis and simultaneously rotates inside the furnace, ensuring uniform heating on each side.

⭐PATENT SYSTEM

Separate temperature management

The furnace is divided into two separate overlapping baking chambers to achieve a better quality of the final product and optimize energy consumption.

Easy-to-use intuitive user interface

Intuitive 10" screen interface with visibility of the burnout process, current temperature, alarms and other parameters.

Easy flask loading and unloading

Thanks to the position indicator, the operator finds the flask in front of the door ready for picking.

Program management

Up to 50 different work programs can be set to ensure perfect results on all metals.

Other features

Burnout curve management with 20 steps;

Burnout graph management immediately available;

Temperature control to ensure maximum temperature is not excedeed;

Control of the resistance on wax draining.

TECHNICAL DATA

EcoTech

POWER

230 Vac ±10%, 60 Hz, 3P + N + PE - Max power consumption: 15 kW / 400 Vac ±10%, 50 Hz, 3P + N + PE - Max power consumption: 15 kW

MAX TEMPERATURE

900° C

CAPACITY WITH FLASKS OF Ø 100 mm2

with flanges : 24 flasks / without flanges: 38 flasks

ROTATING STAND

2 supports with Ø= 550 mm

MAX FLASK HEIGHT

300 mm

MAX FLASK DIAMETER (without flanges)

180 mm

FLANGES DIAMETER

120 mm

DISPLAY

Touch screen 10”

WEIGHT

670 Kg

EcoTech

POWER

230 Vac ±10%, 60 Hz, 3P + N + PE - Max power consumption: 15 kW / 400 Vac ±10%, 50 Hz, 3P + N + PE - Max power consumption: 15 kW

MAX TEMPERATURE

900° C

CAPACITY WITH FLASKS OF Ø 100 mm2

with flanges : 24 flasks / without flanges: 38 flasks

ROTATING STAND

2 supports with Ø= 550 mm

MAX FLASK HEIGHT

300 mm

MAX FLASK DIAMETER (without flanges)

180 mm

FLANGES DIAMETER

120 mm

DISPLAY

Touch screen 10”

WEIGHT

670 Kg

Forced-air cooling

Compressed air delivery system

Discover other similar products

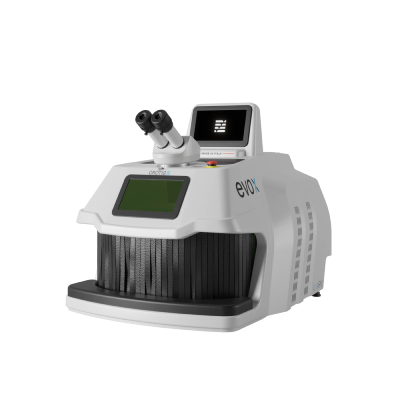

DISCOVER TI CAST

Casting Machine

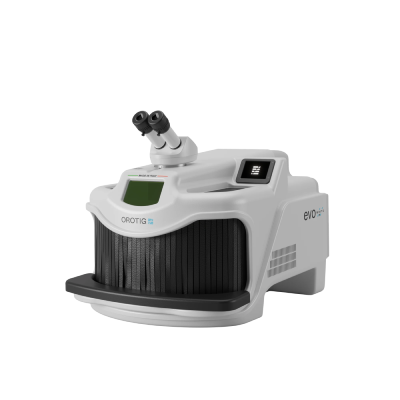

DISCOVER PT CAST

Casting Machine

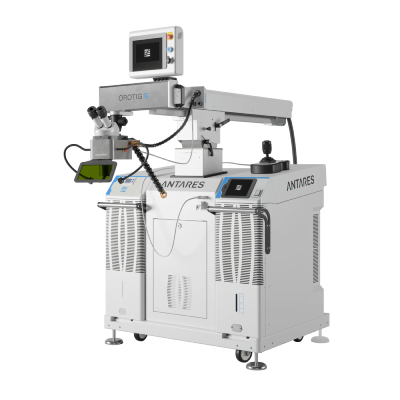

DISCOVER PROMETHEUS

Casting Machine