Superior-quality laser engraving on polished parts

The 3-axis RR Pico laser engraving machine delivers extremely high-quality engravings, free from burrs and burns, thanks to picosecond pulse technology. The coaxial camera and Pattern Matching ensure precise positioning, automatic part recognition, and maximum repeatability.

Superior-quality laser marking on polished parts

The 3-axis RR Pico laser engraving machine delivers extremely high-quality engravings, free from burrs and burns, thanks to picosecond pulse technology. The coaxial camera and Pattern Matching ensure precise positioning, automatic part recognition, and maximum repeatability.

Production efficiency

Pattern Matching automatically recognizes parts, even with different shapes, aligning the design automatically and optimizing batch processing for increased productivity.

Maximum precision

Motorized movement on three axes combined with the coaxial vision system ensures fast and accurate design positioning, guaranteeing high repeatability on every piece.

Ultra-high quality

Ultra-precise, thermally unaffected markings, even on mirror-polished or rhodium-plated surfaces. The extremely short laser pulse duration and small spot size allow marking of very fine details down to 0.1 mm, ensuring perfectly sharp and legible results.

Quality without rework

RR Pico allows marking on already polished or rhodium-plated jewelry, eliminating the sanding and post-polishing steps typically required in traditional processes. Thanks to ultra-short laser pulses that process the material without altering its structure, marking becomes the final stage of the production cycle. The jewelry can be packaged immediately after engraving, reducing process times, rework, and scrap, while ensuring high quality and repeatability.

Ultra-high definition

Thanks to the ultra-short laser pulse and a 0.05 mm spot size, RR Pico can mark details as small as 0.1 mm, ensuring sharp, burr-free engravings.

Cost and resource optimization

The absence of burrs and rework reduces material loss and processing time, optimizing resource usage and ensuring consistent results on every piece.

Marking on heat-sensitive materials

Marking can be performed close to heat-sensitive materials, such as resins, without altering their structure.

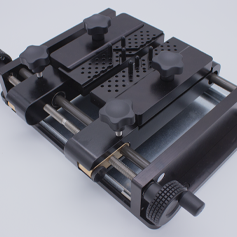

Coaxial system and probe: precision and ease of engraving

The coaxial vision system provides precise visualization of the engraving area, reducing centering errors and setup times. Combined with the touch probe for fast focusing, it ensures maximum repeatability and quality.

Ease of use

The intuitive software allows rapid selection of the recognition area and direct positioning of the job on the image via drag & drop. LED illumination highlights even the smallest imperfections, ensuring fast and accurate alignment.

Production efficiency

The camera and probe eliminate manual errors and simplify workflow, making the system suitable for high-intensity production.

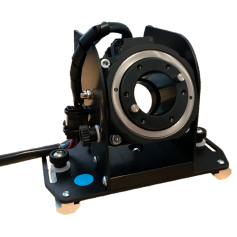

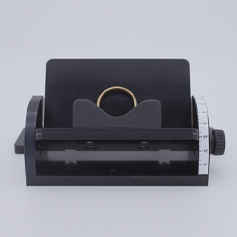

High precision

Ideal for small details, logos, hallmarks, and hard-to-reach areas. It manages the rotary motor for internal and external ring engraving.

Pattern Matching: automatic part recognition

The Pattern Matching function automatically recognizes objects within the field of view, even with different shapes, thanks to the integrated coaxial camera. The system aligns the design and starts marking without jigs or mechanical fixtures, enabling simultaneous marking of multiple parts and efficient batch processing with high precision and repeatability.

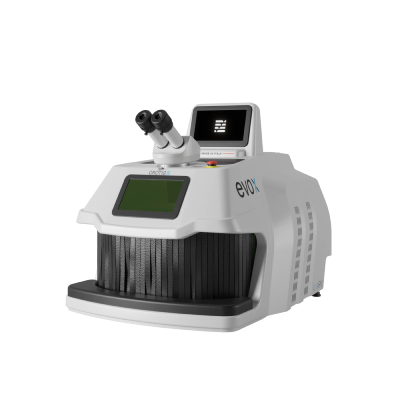

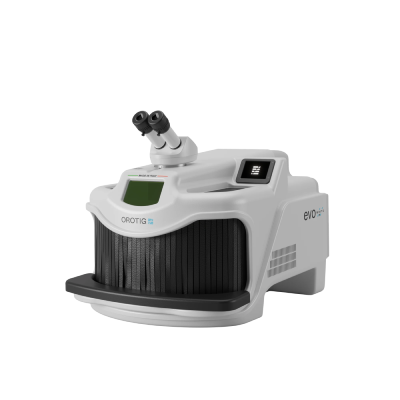

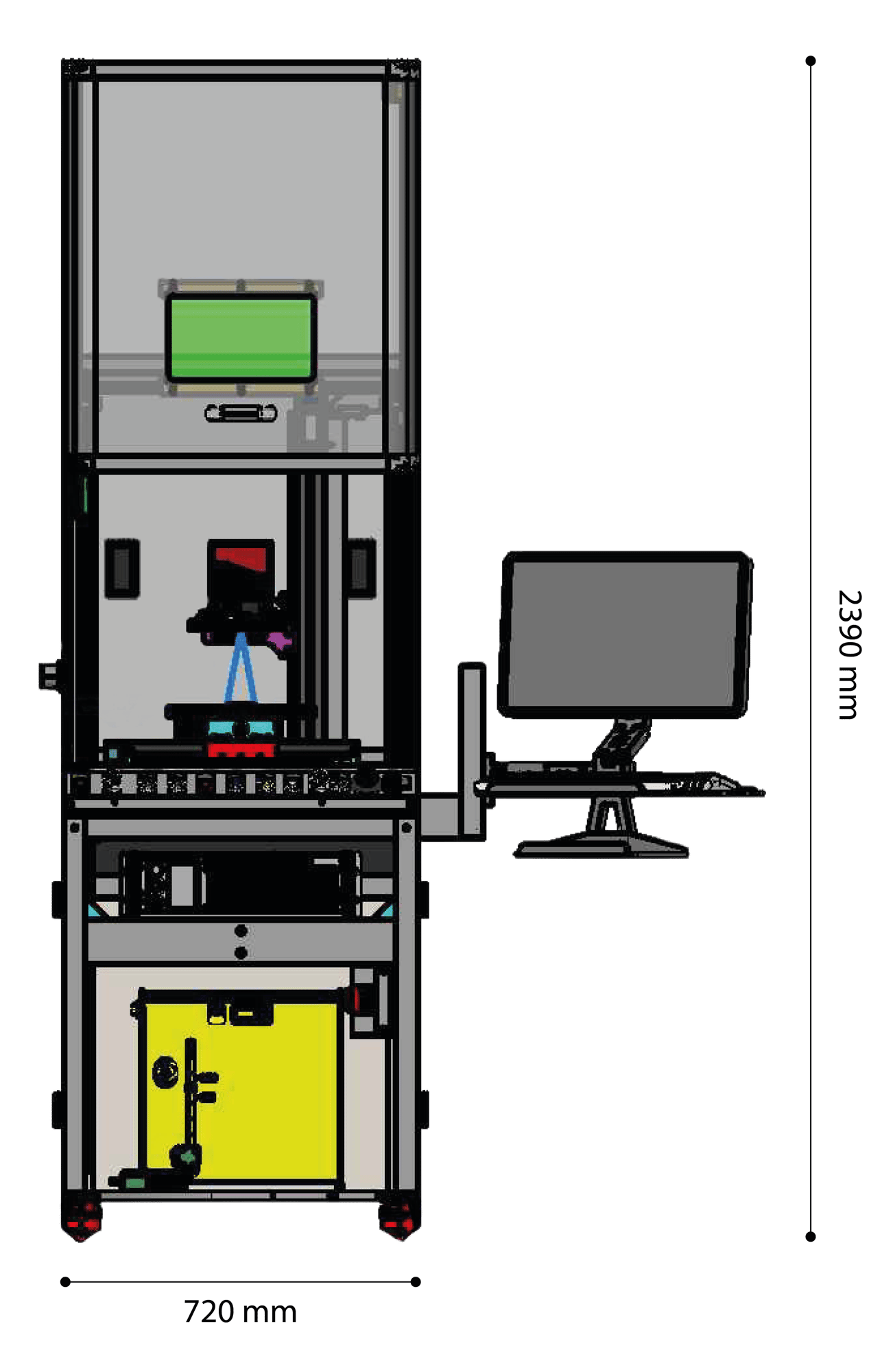

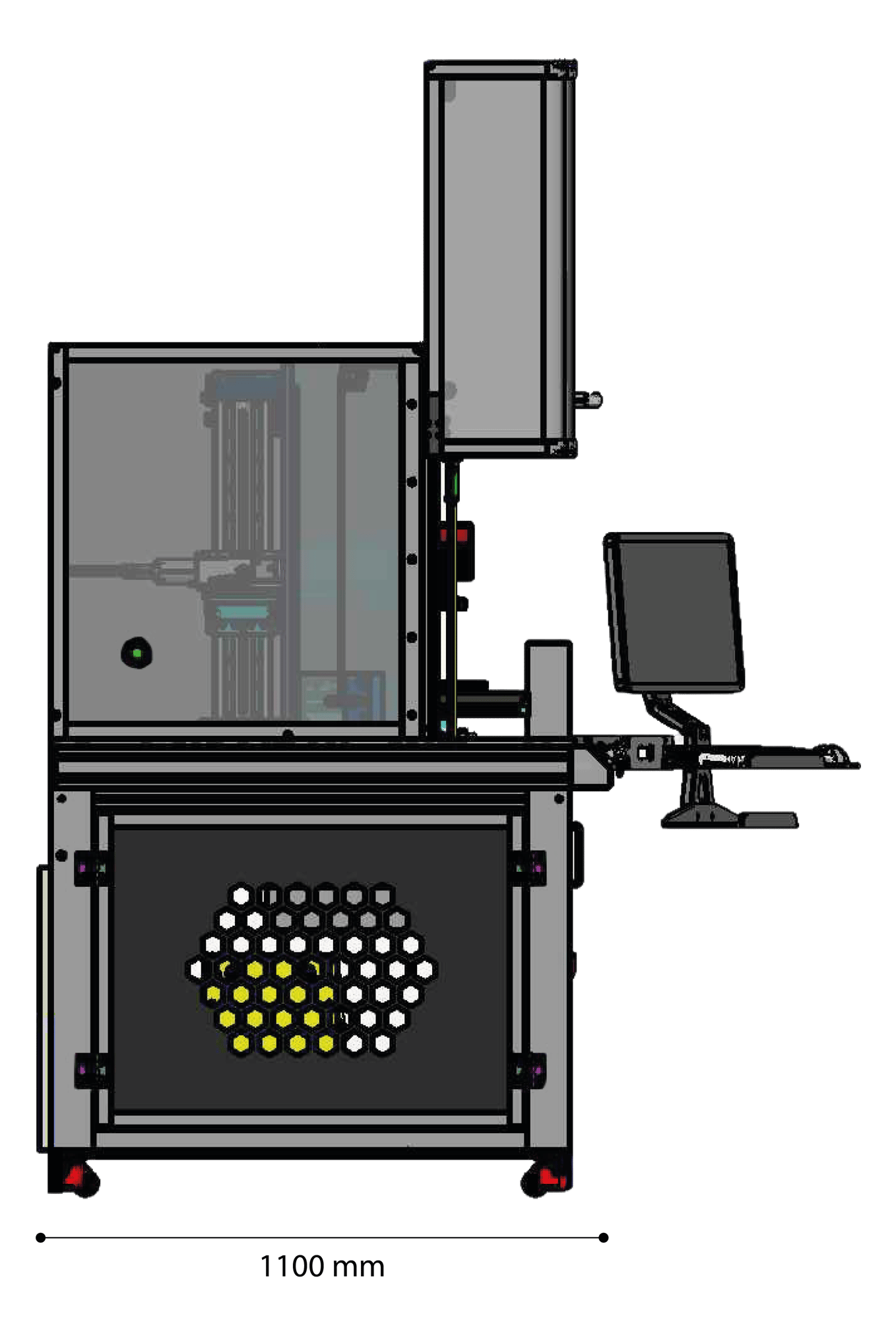

Size and Dimensions

RR Pico stands out for its versatility in laser engraving on metals, silicon, plastics, and ceramics. Ideal for both the production of fine artifacts and jewelry customization, it seamlessly adapts to various manufacturing environments, meeting the high precision demands of medium and large enterprises in the jewelry sector.

- Features

- Technical Data

- Accessories

- Downloads

Dual Vision System

- Coaxial camera for perfect engraving alignment.

- Front USB digital camera for live view of the work area and fast, precise piece positioning.

Telecentric Lens

The 125 mm telecentric lens provides uniform engravings across a 57×57 mm area, eliminating optical distortion.

Clean and Safe Working

Environment

Three-stage vacuum system TBH BF100R:

- synthetic fiber pre-filter;

- HEPA H13 filter for microparticle removal;

- activated carbon filter for gas and odour absorption.

Operational Safety

CE-certified inspection window

provides full visibility of the engraving

process without requiring protective

eyewear.

MARKo Software Integration

Intuitive proprietary interface

guides operators throughout the

engraving process, and enables

automatic management of hallmarks,

serial numbers, barcodes, and QR

codes with progressive indexing.

Focusing System

Independent Z-Axis adjustable via

high-precision Brushless motors.

Pneumatic Door Opening

TECHNICAL DATA

RR Pico

LASER TYPE

Ytterbium Picosecond Fiber Laser

LASER SOURCE

50 W

MARKABLE MATERIALS

Precious and non-precious metals, glass, ceramics

FOCAL LENS

Telecentric - 125 mm

ENGRAVING AREA

57 × 57 mm

Z - AXIS TYPE

Motorized with Mitsubishi Brushless Motor

STROKE OF X-Y-Z AXIS

X 300 mm – Y 300 mm – Z 300 mm

ENGRAVING SPEED

Up to 10 m/s

FREQUENCY

50 kHz - 2750 kHz

PULSE ENERGY

25 μJ

PULSE DURATION

1-3 ps

BEAM QUALITY

≤ 1,4

LASER CLASS

Class 1 (closed), Class 3R (open)

COOLING SYSTEM

Forced air and liquid cooling system

WAVELENGTH

1030 nm

POWER SUPPLY

230V 50Hz 2.0 kW 2P+N+T

PNEUMATIC SUPPLY

Compressed air at 6 bar

SPOT DIAMETER

30 μm

WEIGHT

350 Kg

RR Pico

LASER TYPE

Ytterbium Picosecond Fiber Laser

LASER SOURCE

50 W

MARKABLE MATERIALS

Precious and non-precious metals, glass, ceramics

FOCAL LENS

Telecentric - 125 mm

ENGRAVING AREA

57 × 57 mm

Z - AXIS TYPE

Motorized with Mitsubishi Brushless Motor

STROKE OF X-Y-Z AXIS

X 300 mm – Y 300 mm – Z 300 mm

ENGRAVING SPEED

Up to 10 m/s

FREQUENCY

50 kHz - 2750 kHz

PULSE ENERGY

25 μJ

PULSE DURATION

1-3 ps

BEAM QUALITY

≤ 1,4

LASER CLASS

Class 1 (closed), Class 3R (open)

COOLING SYSTEM

Forced air and liquid cooling system

WAVELENGTH

1030 nm

POWER SUPPLY

230V 50Hz 2.0 kW 2P+N+T

PNEUMATIC SUPPLY

Compressed air at 6 bar

SPOT DIAMETER

30 μm

WEIGHT

350 Kg

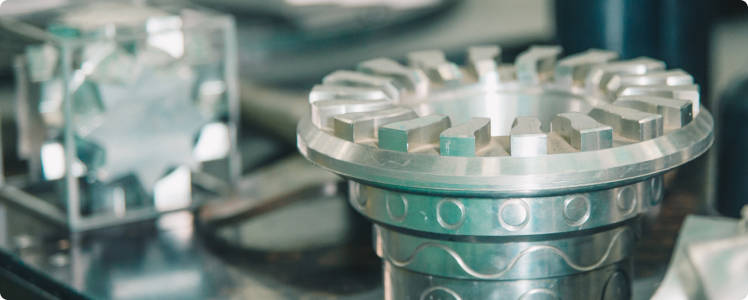

Rotary & Spindles

Tiltable Support

3 in 1 clamp

Touch Probe

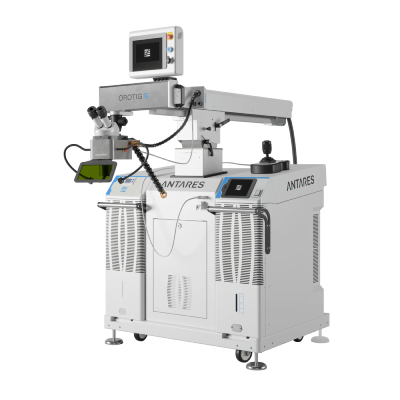

Discover other similar products

DISCOVER CELLINI

Laser Engraving Machine

DISCOVER CANOVA

Laser Engraving Machine

DISCOVER RR NEXT

Laser Engraving Machine