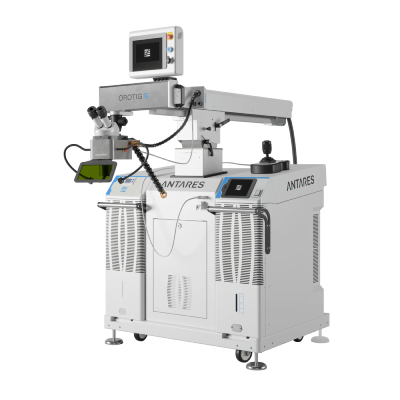

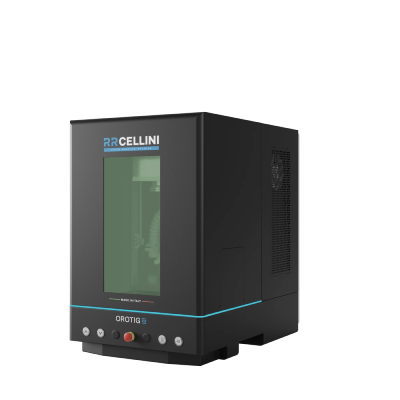

High-performance casting machine for gold and silver

Casting machine for gold and silver, also compatible with brass and bronze, designed for the needs of high jewelry, fashion, and eyewear industries. The patented horizontal casting system ensures consistent quality and repeatable casting cycles.

High-performance casting machine for gold and silver

Casting machine for gold and silver, also compatible with brass and bronze, designed for the needs of high jewelry, fashion, and eyewear industries. The patented horizontal casting system ensures consistent quality and repeatable casting cycles.

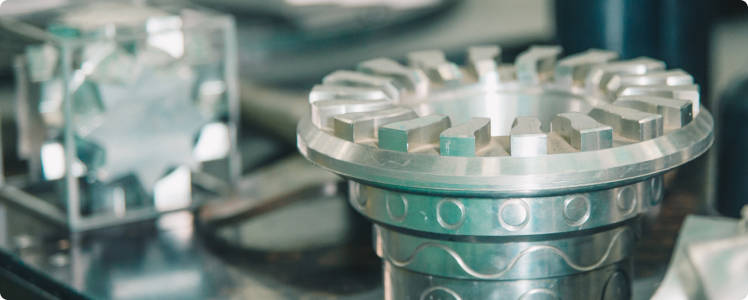

High casting quality

Helios ensures perfectly smooth, porosity-free castings with exceptional alloy homogeneity, thanks to its inline casting system that enables the rapid transfer of molten metal, minimizing temperature loss.

Ease of use

The 10ˮ capacitive touch screen provides real-time monitoring of all casting parameters. Helios features preset programs for gold, silver, and non-precious alloys, plus 50 customizable profiles for quick and intuitive management of every casting cycle.

Production efficiency

The automatic flask locking and tilting system reduces setup times and ensures maximum process repeatability. The patented design guarantees complete flask filling without the use of seals or stoppers, reducing operational costs and simplifying maintenance.

Patented casting technology

With its patented linear casting system, Helios features a horizontal crucible that aligns perfectly with the flask, enabling direct, swift pouring. This design minimizes temperature drops and vortices, improving the quality of your castings. Automatic vacuum and overpressure functions ensure complete filling of the flask, producing smooth, compact surfaces.

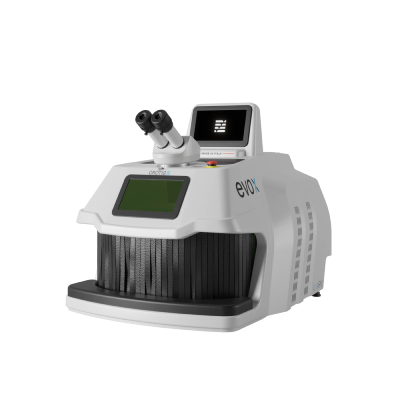

Simple Interface and Advanced Digital Control

Helios is designed to ensure outstanding performance in precious metal casting. With a 10" touchscreen display and advanced digital management, it delivers superior performance and real-time monitoring of casting parameters, ensuring maximum precision at every stage.

Intuitive interface

The 10" capacitive display allows real-time monitoring of casting parameters, making process management fast and straightforward.

Customizabile programs

Preset programs for gold, silver, and other alloys, with the possibility to create up to 50 custom programs. to adjust parameters such as temperature, duration, and cooling speed based on specific casting needs.

Connectivity and industry 4.0 integration

Equipped with Ethernet connectivity for remote monitoring and support, Helios complies with Industry 4.0 standards, allowing seamless integration into interconnected production systems while ensuring high performance and maximum efficiency.

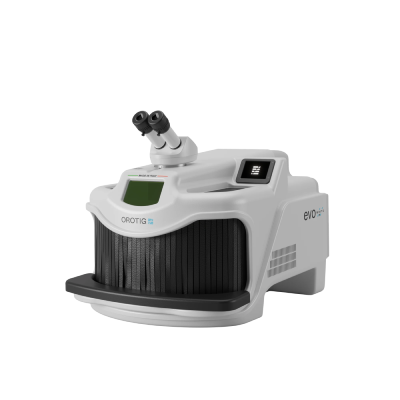

Versatile Design and Functionality for Every Need

The Helios casting machine is available in both benchtop and integrated support base version, to accommodate the external chiller and vacuum pump. Both configurations include a practical drawer with a refractory stone, ideal for storing crucibles, tongs, and other essential tools, ensuring an organized workspace and optimizing efficiency during the casting process.

- Features

- Technical Data

- Accessories

- Downloads

Flexible solution

Available both as a benchtop version

and with an integrated support

base, which can accommodate

the external chiller and vacuum pump.

Customizable casting programs

Helios offers preset programs for gold, silver, and other alloys, and allows the creation of up to 50 fully customizable casting programs.

Drawer with refractory stone

Ideal for storing crucibles, tongs, rubber molds, and other essential tools.

User interface and connectivity

Featuring a 10" color touch display and Ethernet connectivity, Helios enables remote monitoring and assistance.

Vacuum and overpressure

The automatic vacuum and overpressure

functions (up to 2 bar) ensure a complete and uniform filling of the flask, including its most intricate branches, delivering castings with smooth and compact surfaces.

Automatic chamber tilting

The chamber rotation is fully automated, with controlled, consistent speed, ensuring maximum process repeatability.

TECHNICAL DATA

Helios

CASTING PROCESS

Induction with controlled atmosphere

MIN CASTING VOLUMES (g)

Gold 18 kt (400 g), Silver (250 g), Brass (200 g), Bronze (200 g)

MAX CASTING VOLUMES (g)

Gold 18 kt (1200 g), Silver (800 g), Brass (700 g), Bronze (700 g)

OVERPRESSURE WITH GAS

Argon 2 bar

VACUUM

10-2 bar

MAX FLASK SIZE (h x Ø, mm)

230 × 120

TEMPERATURE CONTROL

Up to 1200 °C, with thermocouple control

FLASK LOCKING / FILLING

Automatic / Automatic

FLASK FILLING SYSTEM

Tilting

COOLING SYSTEM

External water cooling system

DISPLAY

10” Touch screen

POWER

230 Vac ±10%, 60 Hz, 3P + N + PE - max power consumption 5 kW / 400 Vac ±10%, 50 Hz, 3P + N + PE - max power consumption 5 kW

COMPRESSED AIR

6 bar

MACHINE WEIGHT (+ TRANSFORMER)

310 kg (+ 90 kg)

OPTIONAL ACCESSORIES

Chiller (not included)

Helios

CASTING PROCESS

Induction with controlled atmosphere

MIN CASTING VOLUMES (g)

Gold 18 kt (400 g), Silver (250 g), Brass (200 g), Bronze (200 g)

MAX CASTING VOLUMES (g)

Gold 18 kt (1200 g), Silver (800 g), Brass (700 g), Bronze (700 g)

OVERPRESSURE WITH GAS

Argon 2 bar

VACUUM

10-2 bar

MAX FLASK SIZE (h x Ø, mm)

230 × 120

TEMPERATURE CONTROL

Up to 1200 °C, with thermocouple control

FLASK LOCKING / FILLING

Automatic / Automatic

FLASK FILLING SYSTEM

Tilting

COOLING SYSTEM

External water cooling system

DISPLAY

10” Touch screen

POWER

230 Vac ±10%, 60 Hz, 3P + N + PE - max power consumption 5 kW / 400 Vac ±10%, 50 Hz, 3P + N + PE - max power consumption 5 kW

COMPRESSED AIR

6 bar

MACHINE WEIGHT (+ TRANSFORMER)

310 kg (+ 90 kg)

OPTIONAL ACCESSORIES

Chiller (not included)