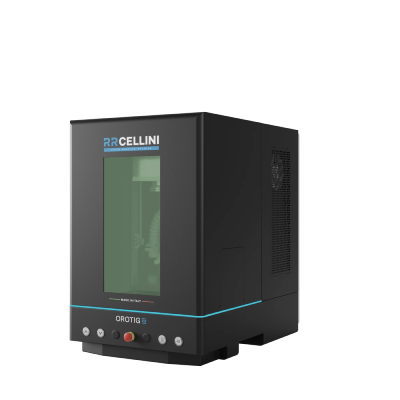

Precision laser engraving and cutting for jewelry creativity

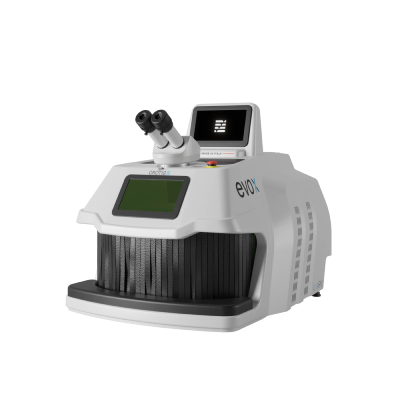

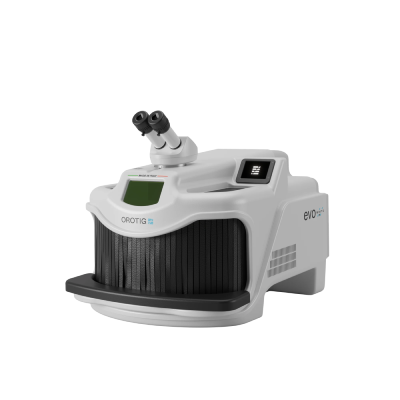

An evolution of the RR laser engraving machine, RR Next delivers high-precision engraving and cutting up to 2 mm on precious metals and alloys. Compact and reliable, it ensures consistent quality, efficiency, and speed, making it ideal for customization and optimized production processes.

Precision laser engraving and cutting for jewelry creativity

An evolution of the RR laser engraving machine, RR Next delivers high-precision engraving and cutting up to 2 mm on precious metals and alloys. Compact and reliable, it ensures consistent quality, efficiency, and speed, making it ideal for customization and optimized production processes.

Maximum precision

The coaxial vision system enables fast and accurate design positioning, reducing learning time and manual errors while ensuring consistently repeatable markings.

Productive efficiency

With the Pattern Matching function, the system automatically recognizes objects—even with different shapes—thanks to the integrated coaxial camera, optimizing batch processing and significantly increasing productivity.

Versatile

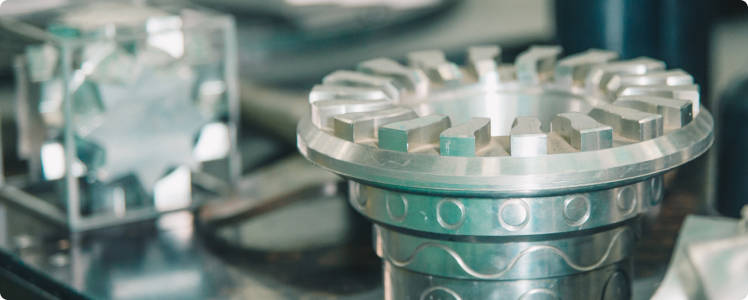

Available with a range of laser sources at different power levels, configurable according to finishes and processed metals. This flexibility allows engraving, marking, micro-cutting, and cutting up to 2 mm in serial production.

Coaxial system and probe: precision and ease of engraving

The coaxial vision system provides precise visualization of the engraving area, reducing centering errors and setup times. Combined with the touch probe for fast focusing, it ensures maximum repeatability and quality.

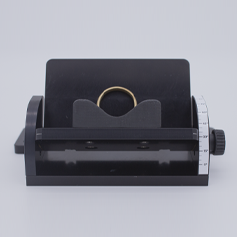

High precision

Accurate marking of details such as logos and hallmarks, even in hard-to-reach areas. The rotary motor allows internal and external ring processing in compliance with high jewelry standards.

Production efficiency

The coaxial camera and touch probe eliminate manual errors, optimizing quality and speed for repetitive laser engraving tasks. The streamlined workflow reduces setup times, accelerating mass production.

Ease of use

Intuitive software to quickly select the recognition area and position the job directly on the image via drag & drop.

MARKo: the Intuitive Software for Laser Engraving in Just a Few Clicks

Thanks to the new proprietary MARKo software, even less experienced operators can perform engraving operations in just a few clicks, with no margin for error. The guided procedure intuitively supports the operator throughout the entire process, allowing existing files to be imported or text to be created from scratch.

Preset parameters for different metals enable professional results even for beginners, with the option to create custom settings based on specific processing needs.

Guided engraving

Guided tours accompany the operator through the various steps and reduce the margin of error.

Animated tooltips

Tooltips explain the software functionality, also for people using the engraving machine for the first time.

Preset parameters

To enable even less-experienced operators to perform professional engraving, the engraving parameters can be set independently or one of our predefined programs can be chosen.

MARKo: the Intuitive Software for Laser Engraving in Just a Few Clicks

Thanks to the new proprietary MARKo software, even less experienced operators can perform marking operations in just a few clicks, with no margin for error. The guided procedure intuitively supports the operator throughout the entire process, allowing existing files to be imported or text to be created from scratch.

Preset parameters for different metals enable professional results even for beginners, with the option to create custom settings based on specific processing needs.

Fast and automatic workpiece recognition

The Pattern Matching function automatically detects objects within the field of view, even with different shapes, thanks to the integrated coaxial camera. Once the part is recognized, the system aligns the design and starts engraving with maximum precision without templates or mechanical fixtures ensuring speed and repeatability.

Versatility for every engraving requirement

With configurable laser sources, RR Next enables engraving, marking, and laser cutting up to 2 mm thick, including serial production. Selecting the most suitable source based on material and finish ensures flexibility and full process control. MOPA sources, in particular, are ideal for high-precision, high-contrast engravings, delivering superior definition and quality.

Versatility for every engraving requirement

With configurable laser sources, RR Next enables engraving, marking, and laser cutting up to 2 mm thick, including serial production. Selecting the most suitable source based on material and finish ensures flexibility and full process control. MOPA sources, in particular, are ideal for high-precision, high-contrast engravings, delivering superior definition and quality.

Compact and safe

With a clean design and reduced footprint, RR Next integrates easily into limited spaces while ensuring maximum safety. As a Class 1 laser system, it features a CE-certified inspection window and safety sensors that prevent operation with the door open, allowing use without protective eyewear.

- Features

- Technical Data

- Accessories

- Downloads

Maximum safety

Thanks to the CE-certified inspection window, marking can be done with the door closed, without the need for protective glasses.

Automatic door opening

Air cooling

The air cooling system eliminates the need for an external chiller and machine preheating, simplifying operational management.

Integration with MARKo Software

The RR Nextcomes with MARKo software, a user-friendly interface that guides operators through the entire engraving process, making it ideal for beginners. For more advanced features, the machine also includes Samlight software, tailored for experienced operators seeking enhanced funcionalities.

Focus adjustment

Digitally adjustable Z-axis for precise focusing.

Integrated camera and coaxial camera

The integrated camera allows the operator to view and monitor the process, while the coaxial camera ensures precise visualization of the engraving point.

RGB LED Lighting system

The LED strip lights up in different colors, providing clear and immediate information of the operational state of the engraving machine.

TECHNICAL DATA

RR Next

TYPE OF LASER

Diode pumped fibre (Yb)

POWER RANGES AVALIABLE

30 W, 50 W, 30 W MOPA, 60 W MOPA, 70 W HD, 100 W HD

ADDITIONAL INTEGRATIONS

Coaxial Vision System

Pattern Matching

RECOMMENDED APPLICATIONS

Laser engraving

Logo and hallmark engraving

Photo engraving

Deep engraving of logos, texts, serial numbers, and barcodesProduction of tags, medals, and other personalized items

Micro-cutting of thin plates and components

Cutting up to 2 mm thickness (depending onmaterial)

TYPE OF MATERIAL THAT CAN BE ENGRAVED

All precious and non-precious metals, ceramics, someplastics, and glass (only for light, flat-surface engraving)

FOCAL LENSES AVALIABLE

100 mm, 160 mm (standard lens), 210 mm

ENGRAVING AREA

60 x 60 mm (with 100 mm focal lens)

110x110 mm (with 160 mm focal lens)

145x145 mm (with 210 mm focal lens)

TYPE OF Z AXIS

Motorized with touch probe and software control

STROKE Z AXIS

347 mm

MAXIMUM OBJECT DIMENSIONS IN THE ENGRAVING CHAMBER (L x W x H)

375 x 280 x 251 mm (with 1 00 mm focal lens)

375 x 280 x 175 mm (with 160 mm focal lens)

375 x 280 x 114 mm (with 210 mm focal lens)

MAX WEIGHT OK WORKPIECE

20 kg

SPEED

Up to 8,000 m/s

FREQUENCY

1.0 kHz - 4000 kHz

SAFETY CLASS

Class 1 (hatch closed), Class 3R (hatch open)

SOFTWARE

MARKo/Samlight or EZ Cad

COOLING SYSTEM

Forced air

WAVELENGHT

1064 nm

POWER

230 Vac ± 10%, 50/6 0 Hz, 1P + N + PE, 1. 0 kW Max

WEIGHT

71-75 kg

RR Next

TYPE OF LASER

Diode pumped fibre (Yb)

POWER RANGES AVALIABLE

30 W, 50 W, 30 W MOPA, 60 W MOPA, 70 W HD, 100 W HD

ADDITIONAL INTEGRATIONS

Coaxial Vision System

Pattern Matching

RECOMMENDED APPLICATIONS

Laser engraving

Logo and hallmark engraving

Photo engraving

Deep engraving of logos, texts, serial numbers, and barcodesProduction of tags, medals, and other personalized items

Micro-cutting of thin plates and components

Cutting up to 2 mm thickness (depending onmaterial)

TYPE OF MATERIAL THAT CAN BE ENGRAVED

All precious and non-precious metals, ceramics, someplastics, and glass (only for light, flat-surface engraving)

FOCAL LENSES AVALIABLE

100 mm, 160 mm (standard lens), 210 mm

ENGRAVING AREA

60 x 60 mm (with 100 mm focal lens)

110x110 mm (with 160 mm focal lens)

145x145 mm (with 210 mm focal lens)

TYPE OF Z AXIS

Motorized with touch probe and software control

STROKE Z AXIS

347 mm

MAXIMUM OBJECT DIMENSIONS IN THE ENGRAVING CHAMBER (L x W x H)

375 x 280 x 251 mm (with 1 00 mm focal lens)

375 x 280 x 175 mm (with 160 mm focal lens)

375 x 280 x 114 mm (with 210 mm focal lens)

MAX WEIGHT OK WORKPIECE

20 kg

SPEED

Up to 8,000 m/s

FREQUENCY

1.0 kHz - 4000 kHz

SAFETY CLASS

Class 1 (hatch closed), Class 3R (hatch open)

SOFTWARE

MARKo/Samlight or EZ Cad

COOLING SYSTEM

Forced air

WAVELENGHT

1064 nm

POWER

230 Vac ± 10%, 50/6 0 Hz, 1P + N + PE, 1. 0 kW Max

WEIGHT

71-75 kg

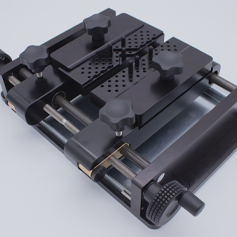

ROTARY & INTERNAL/

EXTERNAL RING CHUCK

CHUCK FOR IRREGULAR RINGS

CHUCK FOR BRACELETS

3-IN-1 CLAMP

TILTING ANGLED SUPPORT

HONEYCOMB SUPPORT

AUTOMATIC SHEET FEEDER

TOUCH PROBE

TBH BF 100 R, TBH BF LN 230

SUPPORT TABLE WITH TBH EXTRACTION SYSTEM COMPART

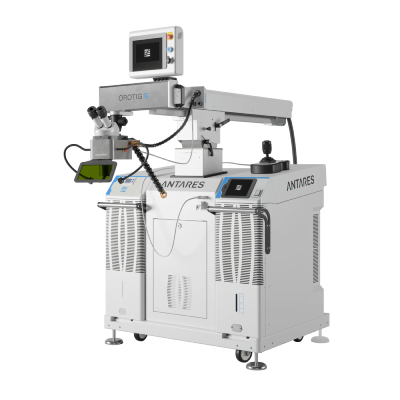

Discover Other Similar Products

DISCOVER RR PICO

Laser Engraving Machine

DISCOVER CANOVA

Laser Engraving Machine