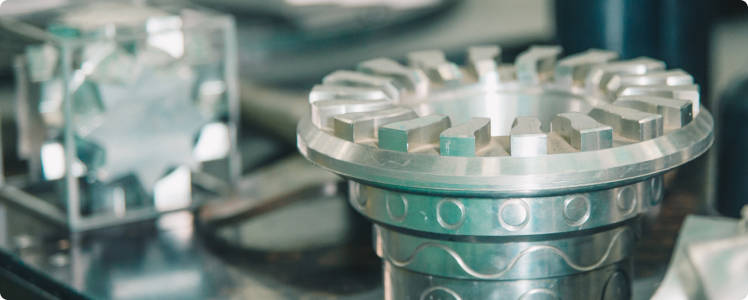

Industrial Laser Welder for Mould Repair

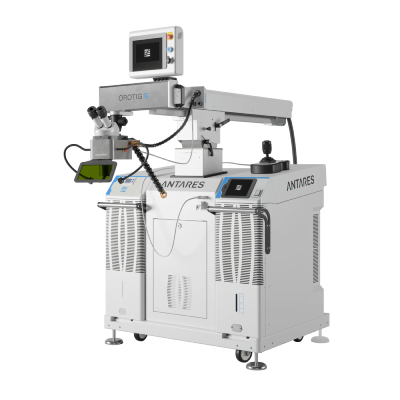

Antares is an industrial laser welding machine designed for repairing moulds or large workpieces. With a motorized arm, it can weld at points that would otherwise be difficult to reach.

Industrial Laser Welder for Mould Repair

Antares is an industrial laser welding machine designed for repairing moulds or large workpieces. With a motorized arm, it can weld at points that would otherwise be difficult to reach.

Semi-automatic functionalities

Intuitive software equipped with semi-automatic functions, ideal even for less experienced operators.

Continuous cycle

An integrated chiller, high frequency and high peak power make Antares ideal for continuous operation.

Wide range of movement

Welds even in hard-to-reach areas through X-Y-Z movements and the articulation of the welding head.

Increases productivity with continuous duty cycles

With an integrated chiller, high frequency and high peak power, Antares is designed to support continuous laser welding cycles 24/7, eliminating the need for machine downtime and improving productivity and company workflows.

High peak power

12,5 kW

Large tank

Water cooling system with an 8 l tank

High frequency

Up to 40 shots per second

Simplified work cycles

Semiautomatic functions, such as memorizing paths like a polyline, memorizing the inclined plane, the circle function and the automation of one of the axes simplify and speed up laser welding operations, even when carried out by less-experienced operators.

Function library

A wide array of semiautomatic features.

Intuitive interface

An easy-to-use 7” colour touch-screen display to easily change the settings.

Overlap functionality

A constant shot distance can be set regardless of the axis speed to obtain uniform laser welding, even in manual mode.

Maximum flexibility and mobility

With the combination of different arm movements, Antares makes it possible to work easily on points that are difficult to reach, even on pieces of a significant size and weight.

Flexible movements

Complete 180° arm rotation and vertical inclination to reach different heights, from 25 cm to 160 cm, ensuring great versatility during laser welding stages.

Adjustable head

Full 360° movement to allow welding on corners and complex geometries.

Easy handling

Anchoring feet to guarantee stability and operator safety and a wheeled base to move the machine easily and quickly.

Maximum flexibility and mobility

With the combination of different arm movements, Antares makes it possible to work easily on points that are difficult to reach, even on pieces of a significant size and weight.

Flexible movements

Complete 180° arm rotation and vertical inclination to reach different heights, from 25 cm to 160 cm, ensuring great versatility during laser welding stages.

Adjustable head

Full 360° movement to allow welding on corners and complex geometries.

Easy handling

Anchoring feet to guarantee stability and operator safety and a wheeled base to move the machine easily and quickly.

Sizes and dimensions

The motorized arm of the Antares industrial laser welder rotates up to 180° and tilts from 25 to 160 cm, allowing work at various heights and access to difficult points. Thanks to the integrated wheels, the machine can be easily moved, while the fixing feet ensure stability and safety during laser welding operations.

- Features

- Technical Data

- Accessories

- Downloads

Semi-automation

Basic software with semi-automation functionality (memorising inclined planes, setting of circumferences or straight lines etc.).

Leica Microscope

Leica 45° Stereo Microscope with 10x optical zoom and aiming crosshair.

Vacuum

Exhauster and Argon fittings.

Facilitated handling

Based on wheels for movement in space,

fixing feet for stability and safety.

TECHNICAL DATA

Antares

CRYSTAL TYPE

Nd:YAG @ 1064 [x 2]

MAX IMPULSE ENERGY

100 J

PULSE DURATION

0.5 - 25 ms

PEAK POWER

12.5 kW

AVERAGE POWER

300 W

REPETITION FREQUENCY

0 - 40 Hz

POWER SUPPLY

400 Vac ±10%, 3P + N + PE, 50/60 Hz, 9 kW

WELDING SPOT DIAMETER

0.7 to 2 mm

COOLING TYPE

Forced air with double circuit with integrated chiller, 8 l liquid and double radiator

DIAMETER - FIBER LENGTH

1000 μm - 5 m

DIMENSIONS (L x P x H)

1020 × 1650 × 1650 mm

WEIGHT

390 Kg

Antares

CRYSTAL TYPE

Nd:YAG @ 1064 [x 2]

MAX IMPULSE ENERGY

100 J

PULSE DURATION

0.5 - 25 ms

PEAK POWER

12.5 kW

AVERAGE POWER

300 W

REPETITION FREQUENCY

0 - 40 Hz

POWER SUPPLY

400 Vac ±10%, 3P + N + PE, 50/60 Hz, 9 kW

WELDING SPOT DIAMETER

0.7 to 2 mm

COOLING TYPE

Forced air with double circuit with integrated chiller, 8 l liquid and double radiator

DIAMETER - FIBER LENGTH

1000 μm - 5 m

DIMENSIONS (L x P x H)

1020 × 1650 × 1650 mm

WEIGHT

390 Kg

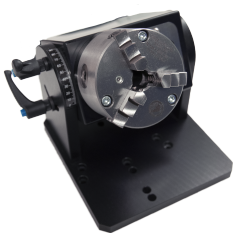

Rotary motor with chuck (Ø 80mm)

Integrated camera connected to external PC

Spherical magnetic holder

Discover other similar products

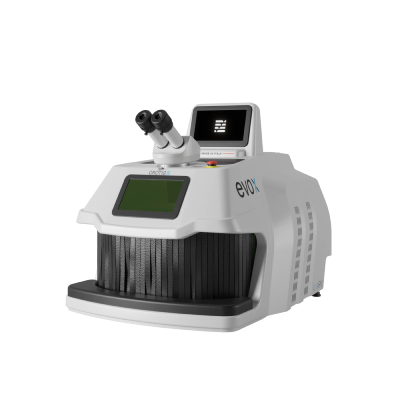

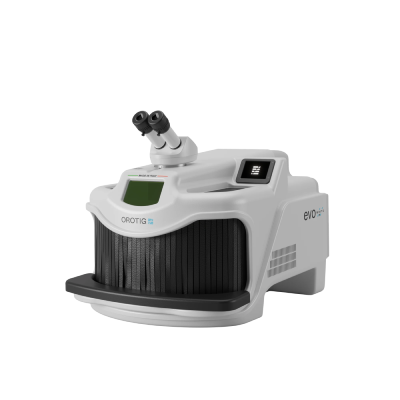

DISCOVER ARIES

Laser welding machine

DISCOVER TDL 500

Laser cutting machine

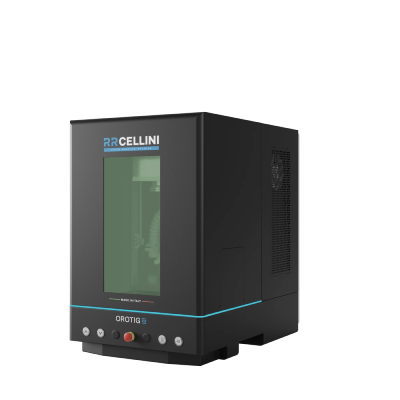

DISCOVER CELLINI

Laser marking machine

DISCOVER EVO X

Laser Welding machine