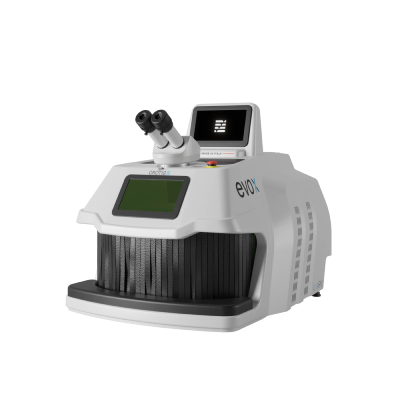

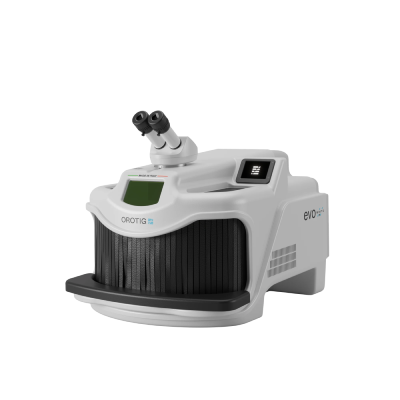

The Most Advanced Titanium Casting Machine

With a chamber capable of casting up to 130 g of titanium at a single time in an argon gas atmosphere, TI Cast is the ideal choice for obtaining extremely high-quality castings in an intuitive way thanks to the interactive touch screen.

The Most Advanced Titanium Casting Machine

With a chamber capable of casting up to 130 g of titanium at a single time in an argon gas atmosphere, TI Cast is the ideal choice for obtaining extremely high-quality castings in an intuitive way thanks to the interactive touch screen.

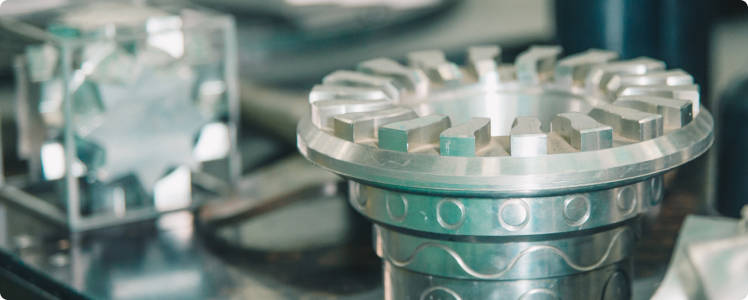

High casting quality

TI Cast delivers a cast product with an excellent finish that needs little further processing.

Short cycle times

Thanks to the new generation plasma TIG system heat is applied directly to the metal, making the casting cycle extremely fast.

Automated operation

While still allowing to manually setting the parameters and rotating the chamber, TI Cast allows the casting process to be set fully automatically.

Size and dimensions

Designed to support continuous casting cycles without limitations on the number of consecutive cycles, Orotig TI Cast ensures efficient and uninterrupted production. Ideal for medium and large-sized companies in the jewelry industry and dental laboratories, it delivers high and reliable performance for titanium casting, ensuring the highest quality even in the most complex operations.

- Features

- Technical Data

- Accessories

- Downloads

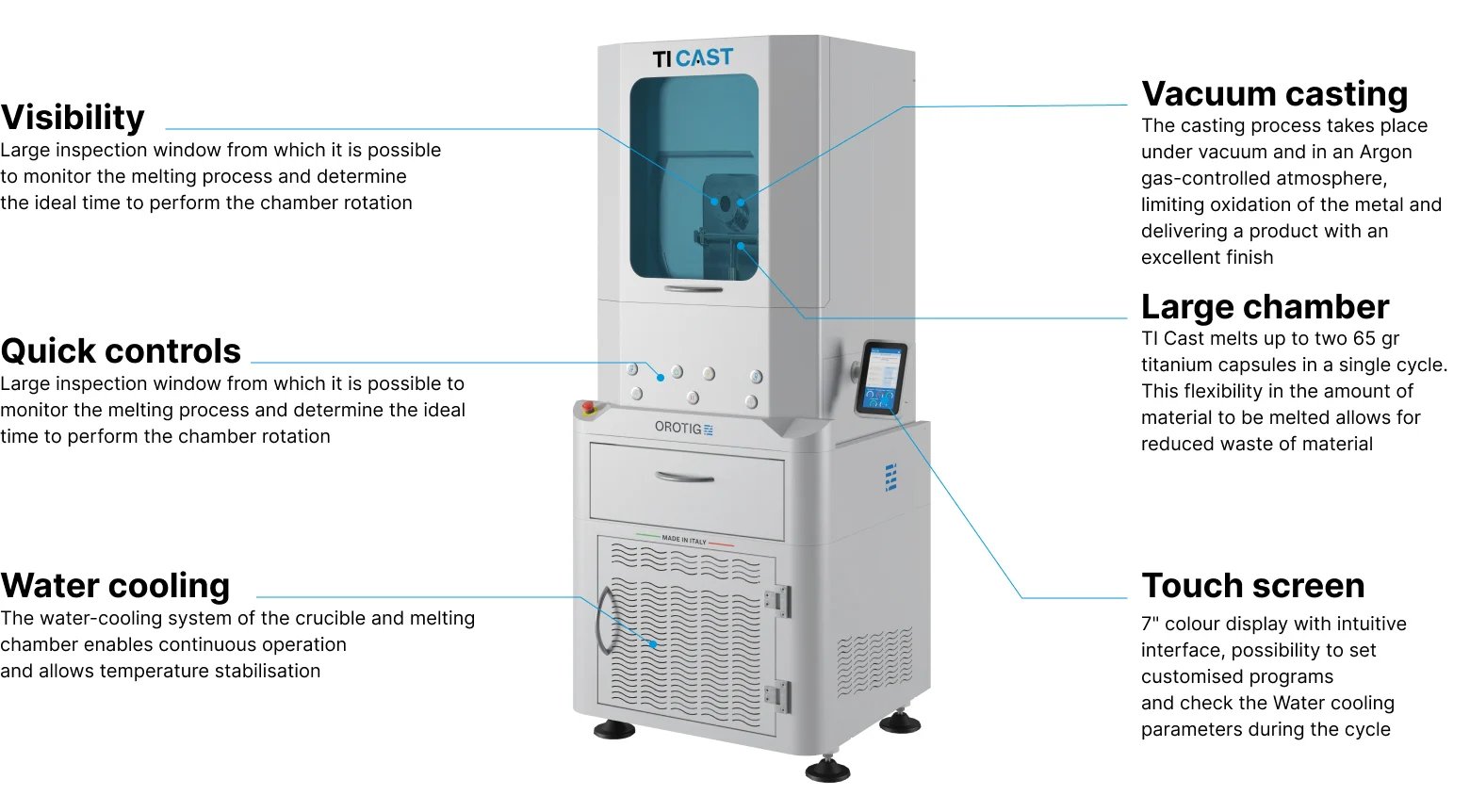

Visibility

Large inspection window from which it is possible to monitor the melting process and determine the ideal time to perform the chamber rotation.

Vacuum casting

The casting process takes place under vacuum and in an Argon gas-controlled atmosphere, limiting oxidation of the metal and delivering a product with an excellent finish.

Quick controls

Main controls in manual mode to facilitate operating the machine with gloves. Once the parameters are set, the buttons allow to complete a cycle without using the touch screen.

Large chamber

TI Cast melts up to two 65 gr titanium

capsules in a single cycle. This flexibility in the amount of material to be melted allows for reduced waste of material.

Water cooling

The water-cooling system of the crucible and melting chamber enables continuous operation and allows temperature stabilisation.

Touch screen

7" colour display with intuitive interface, possibility to set customised programs and check the parameters during the cycle.

TECHNICAL DATA

TI Cast

CASTING PROCESS

TIG/WIG

CASTING VOLUMES (g)

Titanium (130 g)

WORK CYCLE

up to 6 / hour

OVERPRESSURE WITH GAS

Argon 3,5 bar

VACUUM

10-2 bar

MAX FLASK SIZE (h X Ø, mm)

170 × 130

DISPLAY

Touch screen 7”

POWER

400 Vac ±10% 50/60 Hz 3-phase with neutral - max power consumption 18 kW

CASTING MACHINE WEIGHT

400 Kg

GENERATOR WEIGHT

53 Kg

TI Cast

CASTING PROCESS

TIG/WIG

CASTING VOLUMES (g)

Titanium (130 g)

WORK CYCLE

up to 6 / hour

OVERPRESSURE WITH GAS

Argon 3,5 bar

VACUUM

10-2 bar

MAX FLASK SIZE (h X Ø, mm)

170 × 130

DISPLAY

Touch screen 7”

POWER

400 Vac ±10% 50/60 Hz 3-phase with neutral - max power consumption 18 kW

CASTING MACHINE WEIGHT

400 Kg

GENERATOR WEIGHT

53 Kg

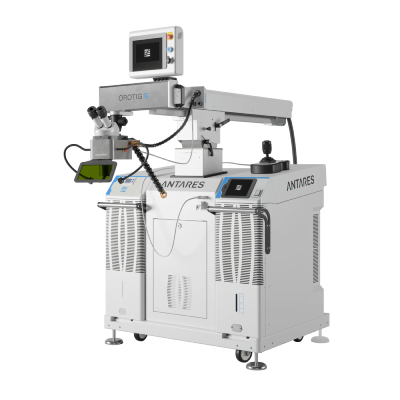

Discover other similar products

DISCOVER ACKERON

Casting Machine

DISCOVER ECOTECH

Furnace