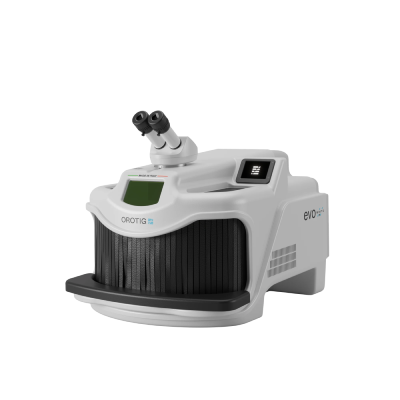

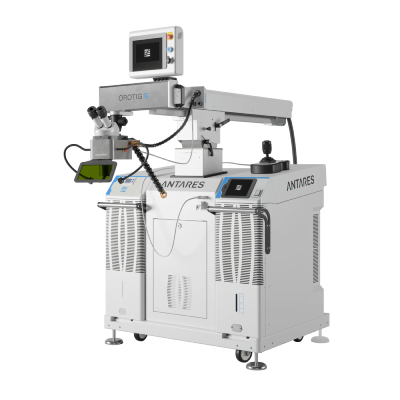

The most advanced platinum casting machine

With a chamber capable of casting up to 500 g of platinum at a single time in an argon gas atmosphere, PT Cast is the ideal choice for obtaining extremely high-quality castings.

The most advanced platinum casting machine

With a chamber capable of casting up to 500 g of platinum at a single time in an argon gas atmosphere, PT Cast is the ideal choice for obtaining extremely high-quality castings.

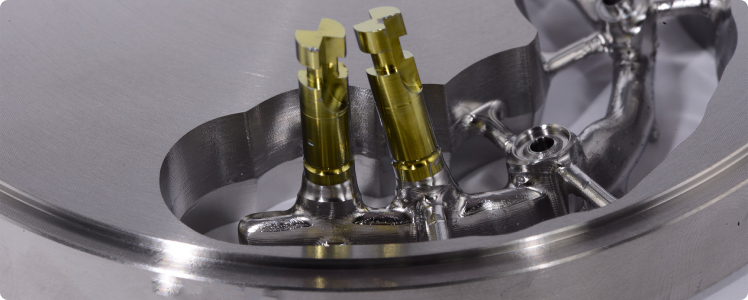

Innovative casting system

The patent-pending linear casting system, with the crucible positioned horizontally and perfectly aligned with the flask, prevents vortices and temperature drops.

Interactive touch screen

Greater operator control due to an interactive touch screen, through which personalised work programs can be set.

Consistent finest results

The perfect filling of the flask ensures perfectly smooth surfaces, without porosity and with a great homogeneity of the alloy, even for filigree jewelry

Size and dimensions

- Features

- Technical Data

- Accessories

- Downloads

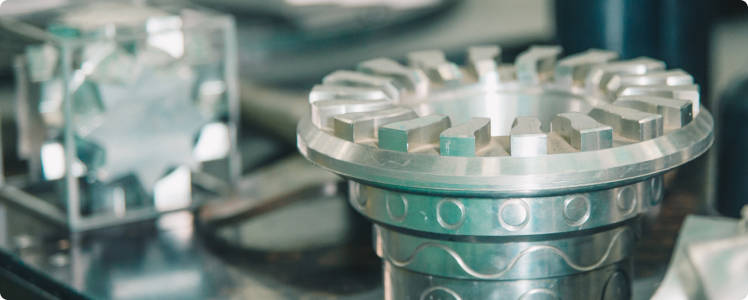

Large chamber

Melting chamber that can melt up to 500 gr of platinum.

Quick Controls

Main controls in manual mode to facilitate operating the machine with gloves. Once the parameters are set, the buttons allow to complete a cycle without using the touch screen.

Touch screen

7" colour display with intuitive interface, possibility to set customised programs and check the parameters during the cycle.

Visibility

Large Inspection window from which you can monitor the merger in progress and determine the ideal time to perform the rollover.

TECHNICAL DATA

PT Cast

CASTING PROCESS

Induction

CASTING VOLUMES (g)

Platinum (500 g)

WORK CYCLE

Up to 6 / hour

OVERPRESSURE WITH GAS

Argon 2 bar

VACUUM

10-2 bar

MAXIMUM FLASK SIZE (h X Ø, mm)

170 × 130

TEMPERATURE CONTROL

Pyrometer, up to 2000° C

FLASK BLOCKING

Automatic

FLASK FILLING

Automatic

FLASK FILLING SYSTEM

Tilting

COOLING SYSTEM

External liquid cooling system (not included)

DISPLAY

Touch screen 7”

POWER

230 Vac ±10%, 60 Hz, 3P + N + PE - max power consumption 5.5 kW / 400 Vac ±10%, 50 Hz, 3P + N + PE - max power consumption 5.5 kW

WEIGHT

400 Kg

PT Cast

CASTING PROCESS

Induction

CASTING VOLUMES (g)

Platinum (500 g)

WORK CYCLE

Up to 6 / hour

OVERPRESSURE WITH GAS

Argon 2 bar

VACUUM

10-2 bar

MAXIMUM FLASK SIZE (h X Ø, mm)

170 × 130

TEMPERATURE CONTROL

Pyrometer, up to 2000° C

FLASK BLOCKING

Automatic

FLASK FILLING

Automatic

FLASK FILLING SYSTEM

Tilting

COOLING SYSTEM

External liquid cooling system (not included)

DISPLAY

Touch screen 7”

POWER

230 Vac ±10%, 60 Hz, 3P + N + PE - max power consumption 5.5 kW / 400 Vac ±10%, 50 Hz, 3P + N + PE - max power consumption 5.5 kW

WEIGHT

400 Kg

Chiller

Discover other similar products

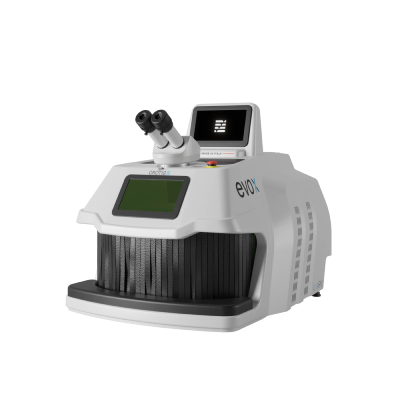

DISCOVER TI CAST

Casting Machine

DISCOVER ECOTECH

Furnace