Back

-

COMPANY

-

SECTORS

-

PRODUCTS

-

-

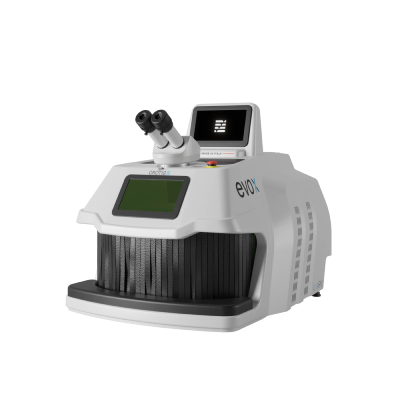

Evo X Tech

Evo X Tech

An enhanced evolution of the renowned Evo X laser welder, the new model features SoftSpot technology for smooth, clean welds on all reflective metals and an optimized duty cycle.

-

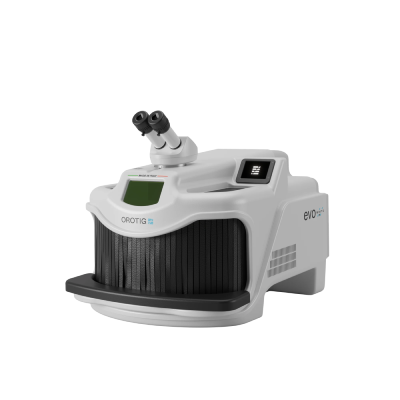

Midi Tech

Midi Tech

The Midi Tech welding machine, reliable and easy to use, is the perfect entry-level solution for small-scale work and repairs in the jewelry and dental fields.

-

Evo X

Evo X

The compact, powerful laser welding machine ensuring maximum precision and reliability, effortlessly delivering superior quality even on reflective metals.

-

Evo White

Evo White

Thanks to its compact design and high-quality components, Evo White is the ideal welder for repairs and customizations in the jewelry and dental fields, ensuring maximum precision and reduced processing times.

-

Revo X

Revo X

The high frequency, peak power and advanced cooling system make Revo X our welding machine with the highest performance, capable of continuous operation for +15 hours.

-

Flash

Flash

The Flash series offers a range of fibre-optic laser sources that can be integrated into production processes requiring a high degree of speed and automation. Compatible with all chain manufacturing machines, they guarantee uniformity and high-quality welds

-

Aries

Aries

The Aries industrial welding machine is able to operate continuously while meeting high quality standards, even on large workpieces, due to the open welding chamber and 3-axis table movement.

-

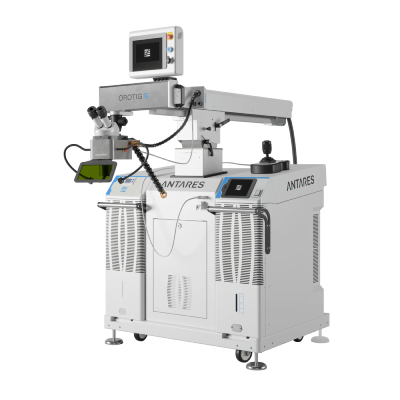

Antares

Antares

Antares is an industrial laser welding machine designed for repairing moulds or large workpieces. With a motorized arm, it can weld at points that would otherwise be difficult to reach.

-

Evo X Tech

-

-

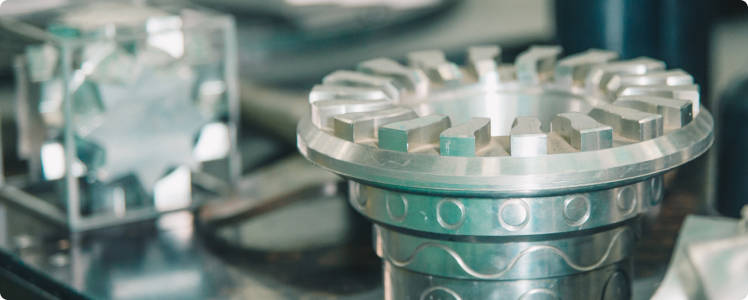

Canova

Canova

New generation of compact laser engraving machines with an essential design, combining high performance, precision, and ease of use thanks to the proprietary MARKo software.

-

RR Next

RR Next - NEW

As the evolution of the RR engraving machine, it ensures precise engraving and cuts up to 2 mm on metals and alloys. Equipped with a coaxial camera for accurate visualization, it is available with various power sources, including MOPA lasers, ideal for high-precision engraving.

-

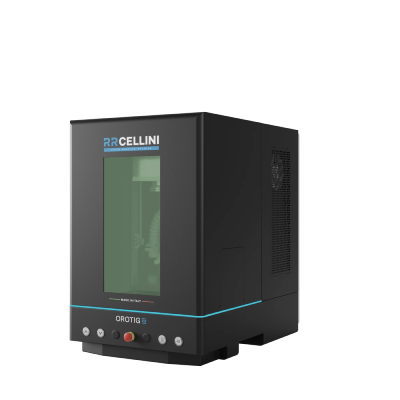

RR Cellini

RR Cellini

The RR Cellini laser engraver machine is a high-precision laser system for quality three-dimensional engraving on metal objects.

-

RR Pico

RR Pico

With a very short laser pulse in the picosecond range, which does not heat up the metal, RR Pico guarantees precise, burr-free, burn-free marking, enabling work even near resins or other heat-sensitive materials.

-

TDL

TDL

Our innovative integrated laser cutting and marking system for large-scale production is capable of precise, high-speed cutting up to 4 mm deep.

-

Canova

-

-

Prometheus

Prometheus

The new standard in precious metal casting: Prometheus, a fully automatic tabletop casting machine for quick and easy custom jewelry creation.

-

Ackeron-PT Cast

Ackeron-PT Cast - NEW

Ackeron-PT Cast is the ideal solution for platinum casting, designed to ensure maximum quality and precision. With its patented horizontal casting system and a 500 g capacity chamber, it guarantees a finished product quality that meets the high standards of fine jewelry.

-

Helios - NEW

Helios

Casting machine for gold and silver, also compatible with brass and bronze, designed for the needs of high jewelry, fashion, and eyewear industries. The patented horizontal casting system ensures consistent quality and repeatable casting cycles.

-

TI Cast

TI Cast

With a chamber capable of casting up to 130 grams of titanium at a single time in an argon gas atmosphere, TI Cast is the ideal choice for obtaining extremely high-quality castings.

-

EcoTech

EcoTech

The two-chamber burnout furnace with an innovative system that allows the burnout of different types of material at the same time, thanks to the ability to set different temperatures for the two chambers or to turn on only one chamber at a time.

-

Prometheus

-

- CUSTOM LINE

-

SERVICE

-

-

Open a Ticket | Technical Support

-

DOWNLOAD SOFTWARE | Remote Assistance

Follow the instructions:- Open a ticket to report the technical issue

- Schedule your meeting with the Service department

- Download the remote support software

-

Open a Ticket | Technical Support

-

-

CONTACT US

Save the date

Save the date

MECSPE 2026

04-06 March 2026

Orotig will be present at MECSPE 2026

Laser Welding in Jewelry: Why It’s Replacing the Flame in Modern Workshops

In jewelry making, welding is one of the most critical and frequent operations. Only a few years ago, flame welding was the only tool available to goldsmiths' workshops for joining precious metals.

Today, laser welding is rapidly becoming the preferred choice for workshops that deal with precious metals and jewelry.

This is more than just a technological evolution: it’s a practical response to the industry’s growing demand for precision, safety, and superior quality.

The main reason lies in the increasing use of heat-sensitive materials, such as emeralds, pearls, and opals, which cannot withstand the high and uncontrolled temperatures produced by an open flame.

The laser, by contrast, enables deep, narrow welds in a minimal heat-affected zone (HAZ), focusing energy on extremely small areas (down to 0.1 mm) and allowing goldsmiths to work just tenths of a millimeter away from delicate components, without damaging them.

What Are the Advantages of Laser Welding in Jewelry and Goldsmithing?

Laser welding offers numerous advantages over traditional flame welding, including greater precision, speed, and versatility.

Compared to traditional flame welding—which produces diffuse heat of 2,500–3,200 °C and a poorly controllable 5–15 mm hotspot—the laser concentrates energy into a 0.1–1.5 mm beam, reaching temperatures up to 5,000 °C with minimal thermal dispersion. This allows precise work on micro-components and gemstones with an extremely low risk of fractures or alterations.

Laser welding also broadens the range of workable materials: not only gold and silver, but also steel, titanium and platinum. It delivers consistently high precision, drastically reducing the need for post-processing and refinishing.

Safety is another major advantage. Flame welding carries a high thermal risk due to direct exposure to the flame and hot components, as well as the use of combustible gases—potentially leading to leaks or explosions. It also produces fumes and vapors that require dedicated extraction systems, and may cause operator fatigue due to less ergonomic working positions.

Laser welding, on the other hand, restricts the heat-affected area to just a few millimetres thanks to the laser’s controlled, pinpoint action. It eliminates the use of gas, reduces fume emissions, and improves operator ergonomics through fixed workstations equipped with high-precision optical and electronic systems.

For a complete comparison with all technical details, a downloadable PDF is available: TABLE

What Can Be Welded With a Laser Welder in Jewelry Making?

Laser welding has expanded the range of processes available in the jewelry industry, becoming one of the most significant innovations for professionals seeking precision, quality, and reliability.

Beyond offering greater safety on heat-sensitive materials, it enables complex repairs and high-precision micromachining. Today, laser welding is used not only in jewelry, but also in silverware, watchmaking, fashion accessories, and eyewear.

Jewelry and Silverware

- Repairs on mounted jewelry: welding prongs on rings with gemstones (emeralds, diamonds, pearls) without removing the stones.

- Invisible welds on jump rings, clasps, prongs, and pavé settings.

- Closing porosity from 3D-printed or cast models, adding prongs, filigree work, and resizing rings.

- Mirror polishing on porous surfaces (platinum and white gold).

- Permanent jewelry: direct welding of bracelets and chains onto the customer’s wrist, in gold or silver, without a clasp (a trend now popular in boutiques and ateliers).

Watchmaking

- Repairs of steel cases, casebacks, bracelets, and dials using laser precision: impossible operations with a flame.

Fashion accessories and eyewear

- Welding on fashion items made of bronze, brass and light alloys, used in fashion accessories, buckles, chains and metal structures.

- Assembly or repair of metal eyeglass frames, even with complex or multi-component designs.

"Laser welding on jewelry: on the left, the components before processing; on the right, the final result achieved with laser technology"

From Workshop to Boutique: Real Experiences

At G&G Amighini Jewelry in Verona, Aldo Amighini shares how laser welding has revolutionized their workflow:

“Before, we avoided working on delicate pieces for fear of damaging them. Today, with the Orotig Evo X laser welder, we can repair a ring’s prong precisely, without removing the stones or affecting the aesthetics. Another revolution is the ability to weld steel, which is essential for watch repairs...”

"Orotig Evo X laser welder and hight adjustable table"

Likewise, Queen Gioielli, a Verona-based fine jewelry atelier, confirms the advantages:

“We discovered this technology thanks to a complex repair on a diamond bracelet. The welding was perfect and invisible. That led to our decision to invest in Orotig Evo X. Today, we can perform special welding operations, such as inserting gold details even near delicate materials, such as ebony, without any risk.”

"Aldo Amighini, G&G Amighini Jewelry, and Marco Fedeli, Queen Gioielli Goldsmith Workshop"

Why Choose a Laser Welder for Jewelry Manufacturing?

In the goldsmithing sector, precision and quality are a must. Lasers allow you to work safely, reduce finishing work, and tackle previously complex operations with ease.

They are not a replacement for the craftsman's hand, but a tool to enhance it, with a quality that is perceived by the end customer as significantly superior.

In a market where every detail matters, laser welding has become a powerful lever for innovation, customer loyalty, and brand prestige.