Back

-

COMPANY

-

SECTORS

-

PRODUCTS

-

-

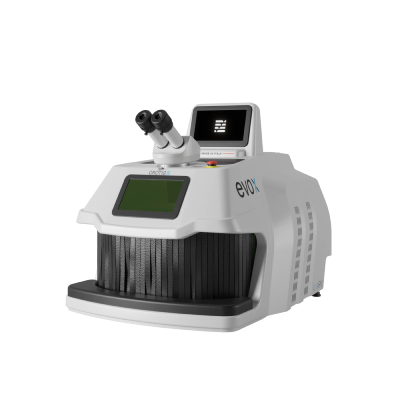

Evo X Tech

Evo X Tech

An enhanced evolution of the renowned Evo X laser welder, the new model features SoftSpot technology for smooth, clean welds on all reflective metals and an optimized duty cycle.

-

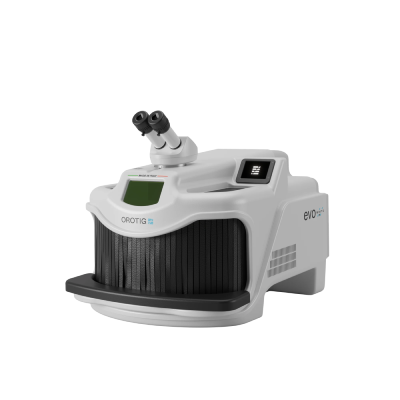

Midi Tech

Midi Tech

The Midi Tech welding machine, reliable and easy to use, is the perfect entry-level solution for small-scale work and repairs in the jewelry and dental fields.

-

Evo X

Evo X

The compact, powerful laser welding machine ensuring maximum precision and reliability, effortlessly delivering superior quality even on reflective metals.

-

Evo White

Evo White

Thanks to its compact design and high-quality components, Evo White is the ideal welder for repairs and customizations in the jewelry and dental fields, ensuring maximum precision and reduced processing times.

-

Revo X

Revo X

The high frequency, peak power and advanced cooling system make Revo X our welding machine with the highest performance, capable of continuous operation for +15 hours.

-

Flash

Flash

The Flash series offers a range of fibre-optic laser sources that can be integrated into production processes requiring a high degree of speed and automation. Compatible with all chain manufacturing machines, they guarantee uniformity and high-quality welds

-

Aries

Aries

The Aries industrial welding machine is able to operate continuously while meeting high quality standards, even on large workpieces, due to the open welding chamber and 3-axis table movement.

-

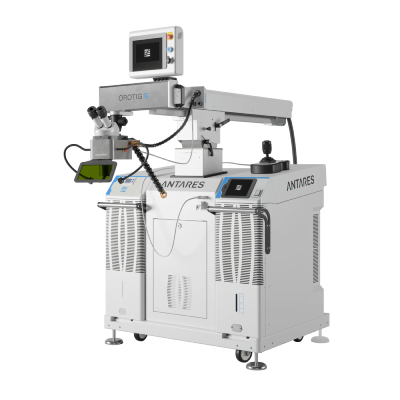

Antares

Antares

Antares is an industrial laser welding machine designed for repairing moulds or large workpieces. With a motorized arm, it can weld at points that would otherwise be difficult to reach.

-

Evo X Tech

-

-

Canova

Canova

New generation of compact laser engraving machines with an essential design, combining high performance, precision, and ease of use thanks to the proprietary MARKo software.

-

RR Next

RR Next - NEW

As the evolution of the RR engraving machine, it ensures precise engraving and cuts up to 2 mm on metals and alloys. Equipped with a coaxial camera for accurate visualization, it is available with various power sources, including MOPA lasers, ideal for high-precision engraving.

-

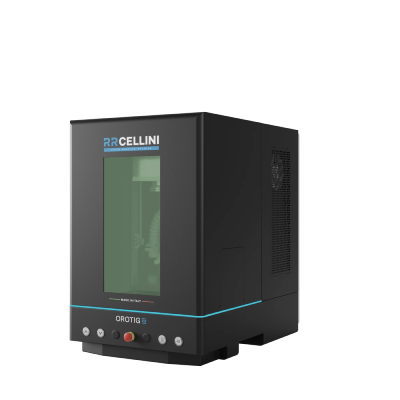

RR Cellini

RR Cellini

The RR Cellini laser engraver machine is a high-precision laser system for quality three-dimensional engraving on metal objects.

-

RR Pico

RR Pico

With a very short laser pulse in the picosecond range, which does not heat up the metal, RR Pico guarantees precise, burr-free, burn-free marking, enabling work even near resins or other heat-sensitive materials.

-

TDL

TDL

Our innovative integrated laser cutting and marking system for large-scale production is capable of precise, high-speed cutting up to 4 mm deep.

-

Canova

-

-

Prometheus

Prometheus

The new standard in precious metal casting: Prometheus, a fully automatic tabletop casting machine for quick and easy custom jewelry creation.

-

Ackeron-PT Cast

Ackeron-PT Cast - NEW

Ackeron-PT Cast is the ideal solution for platinum casting, designed to ensure maximum quality and precision. With its patented horizontal casting system and a 500 g capacity chamber, it guarantees a finished product quality that meets the high standards of fine jewelry.

-

Helios - NEW

Helios

Casting machine for gold and silver, also compatible with brass and bronze, designed for the needs of high jewelry, fashion, and eyewear industries. The patented horizontal casting system ensures consistent quality and repeatable casting cycles.

-

TI Cast

TI Cast

With a chamber capable of casting up to 130 grams of titanium at a single time in an argon gas atmosphere, TI Cast is the ideal choice for obtaining extremely high-quality castings.

-

EcoTech

EcoTech

The two-chamber burnout furnace with an innovative system that allows the burnout of different types of material at the same time, thanks to the ability to set different temperatures for the two chambers or to turn on only one chamber at a time.

-

Prometheus

-

- CUSTOM LINE

-

SERVICE

-

-

Open a Ticket | Technical Support

-

DOWNLOAD SOFTWARE | Remote Assistance

Follow the instructions:- Open a ticket to report the technical issue

- Schedule your meeting with the Service department

- Download the remote support software

-

Open a Ticket | Technical Support

-

-

CONTACT US

Save the date

Save the date

MECSPE 2026

04-06 March 2026

Orotig will be present at MECSPE 2026

Laser Marking for Jewelry: How Personalization Is Revolutionizing the Goldsmithing Industry

Laser marking in jewelry is a growing trend across the goldsmithing world.

In 2025, the concept of luxury has evolved: clients no longer seek just a valuable object, but a unique and personal experience. According to the Altagamma Consumer and Retail Insight 2024, 83% of luxury consumers consider customization essential, and 64% are willing to pay more for an accessory that feels truly personal.

In Italy, jewelry continues to hold deep symbolic value: when asked what they would give to mark a major life event - such as an engagement, wedding, or graduation -33% of Italians said, “a precious piece” (Source: Format Research – Federpreziosi, 2025).

This long-standing emotional bond opens up new opportunities for workshops and brands that want to offer distinctive services: custom laser marking, turns every piece into something unique and unrepeatable.

It’s the possibility to tell a personal story - a name, a date, a symbol - that transforms a simple object into a lasting emotional keepsake.

What Is Laser Marking on Precious Metals and How Does It Work?

Laser marking is now the most precise, clean, and versatile technology for engraving text, symbols, or graphics on precious metals such as gold, silver, and platinum, as well as steel and titanium. The process is non-invasive, extremely localized, and thermally controlled. It is ideal for delicate or small objects.

Key advantages of laser engraving in jewelry making:

-

No need to clamp the piece - no risk of damage.

-

Precision up to one-tenth of a millimeter, ideal for logos, dates, initials, and decorative textures.

-

Fast and repeatable, perfect for on-demand or small-batch personalized production.

-

Easily integrates into the workflow of jewelry workshops thanks to intuitive software and compatibility with vector files.

Thanks to its accuracy, laser marking can also be applied to curved or concave surfaces, or areas difficult to reach manually - such as the inside of a wedding band, the back of a pendant, or the flat links of a bracelet.

Personalization no longer means just names or initials: today, jewelers can engrave symbols, signatures, QR codes, geographic coordinates, fingerprints -anything that tells a story and makes a piece truly personal.

"Examples of laser engraving processes: personalized wedding bands, photo engraving on a pendant, precision marking and cutting on various samples made with Orotig laser systems"

Traditional Vs Laser Marking: Technical Comparison

The adoption of laser marking in jewelry is relatively recent. In the past, hand engraving with a burin or diamond-tip marking were preferred.

Manual engraving remains irreplaceable in artistic contexts, where each detail is shaped by the artisan’s hand -but it requires time, mastery, and cannot be easily replicated.

Diamond-tip marking, while suitable for small engravings, does not offer the same precision or speed as laser marking in jewelry and requires mechanical fixation of the piece. This can lead to deformation or puncturing, especially on thin rings or hollow structures - resulting in damage, wasted time, and loss of materials.

On the other hand, laser marking allows jewelers to engrave with maximum precision even on curved or complex surfaces, working directly from digital files, with no physical contact and no risk of damage. It’s the ideal solution for those seeking precision, speed, and versatility, bridging the gap between craftsmanship and modern production efficiency.

How Laser Marking Is Renewing the Goldsmithing Tradition: The G&G Amighini Case

Aldo Amighini, owner of G&G Amighini Jewelry in Verona, explains how personalization has become a daily request in his workshop:

“More and more clients ask for a unique engraving: an initial, a date, a symbol that represents something personal. Wedding rings, bracelets, and even cufflinks have become storytelling spaces.”

"Aldo Amighini, owner of G&G Amighini Jewelry Store in Verona"

To meet this growing demand, the workshop adopted Orotig’s high-precision laser marking technology, allowing them to perform all engravings in-house with speed, accuracy, and total quality control, even on delicate items.

“Being able to manage everything within our workshop, without outsourcing, means we can guarantee quality, quick turnaround times, and a more complete experience for our clients.”

A choice that demonstrates how tradition and innovation can coexist - staying faithful to craftsmanship while embracing the opportunities of personalization.

Future Outlook: The New Frontier of Laser Marking in Jewelry

For goldsmiths and jewelers looking ahead, innovation means investing in quality, design, and personalization services, enhancing tradition while responding to evolving customer expectations.

Investing in laser marking technologies for jewelry and goldsmithing therefore allows you to strategically position yourself in a constantly evolving sector, where customization is no longer an option but a fundamental element for competing in an increasingly demanding market oriented towards uniqueness.